Approach

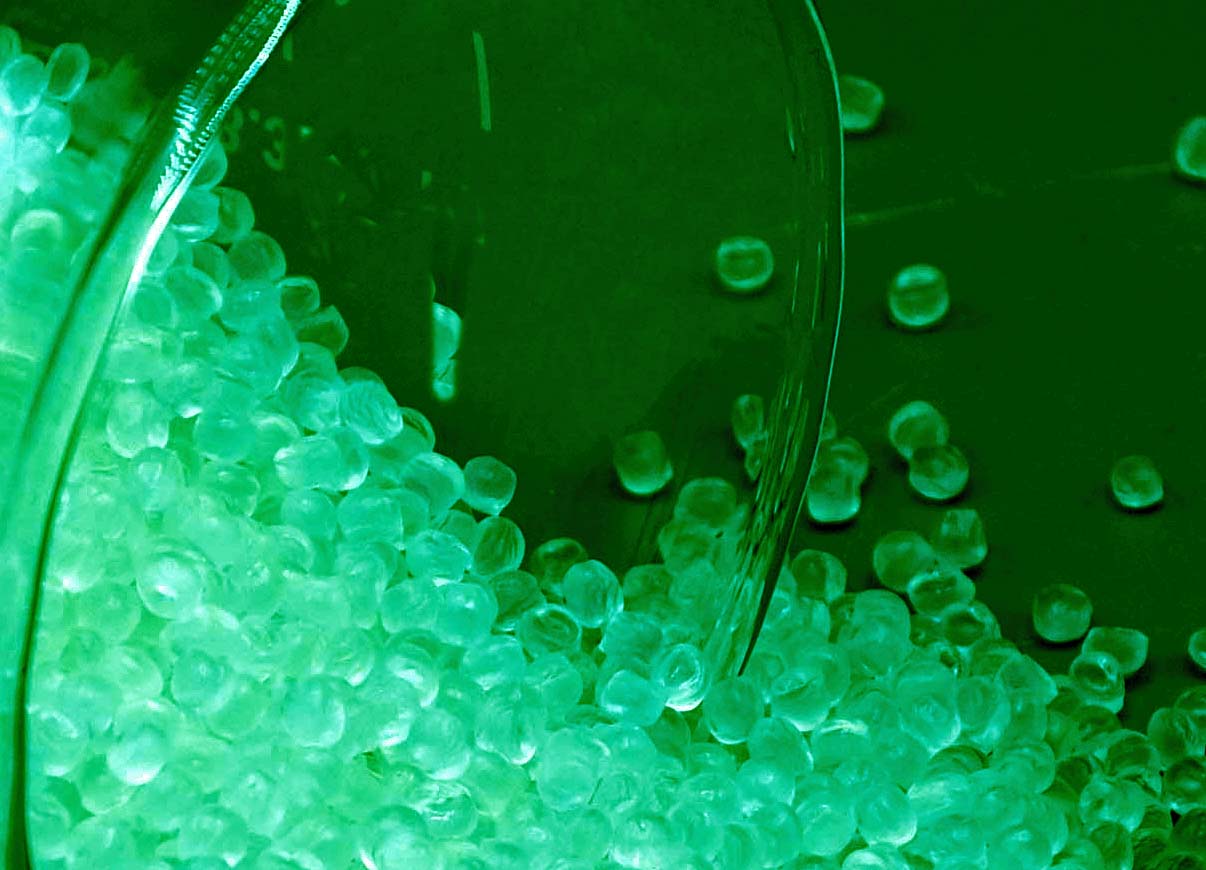

The process begins with the production of yarn from plant-based raw materials, which is then weaved into cleaning textiles. These products are used by consumers and after several months the main step begins: we recycle them. There are two types of recycling: Chemical and mechanical recycling. We use the recycled material to make new yarn from which new cleaning textiles are produced. This starts the cycle all over again. In total we create 3 cycles, started by the same yarn. Our main goal is to analyze each step to create a full life-cycle analysis.