APPROACH

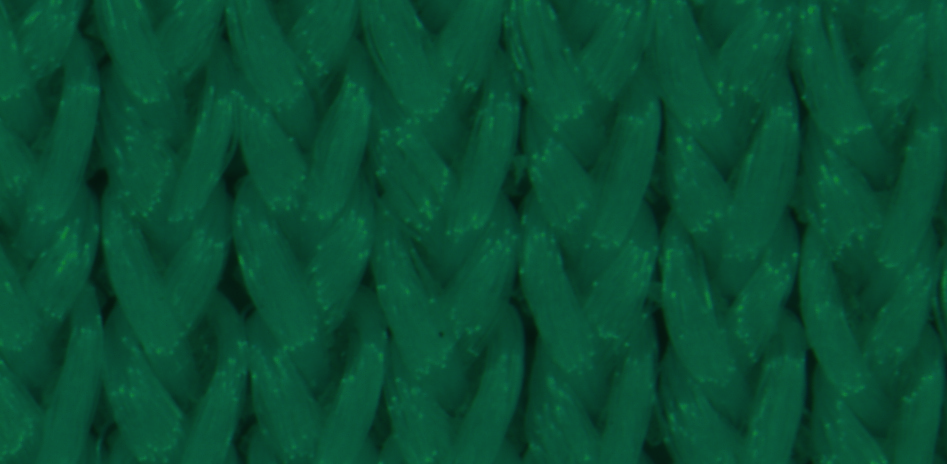

Our project involves several key activities to address the motivation and achieve our goals. Initially, we will develop a collagen spinning process using ionic liquids (ILs) and/or deep eutectic solvents (DES). This involves identifying suitable solvent systems that can dissolve natural and/or recombinant collagen. Concurrently, we will create a requirements catalogue to ensure our materials meet necessary qualitative and quantitative standards. We will conduct laboratory-scale wet spinning of collagen fibres, optimize the coagulation process, and assess the properties of the fibres produced. Finally, we will produce textile demonstrators and prepare communication materials to showcase our findings. This structured approach ensures we develop an environmentally friendly, cost-effective collagen fibre production method with significant industrial potential.